In plastic injection molding, one of the most important aspects of the mold design is how and where it is gated. By definition, an injection molding gate is an orifice through which the molten plastic is injected into the mold.The location, size, and shape of the gate plays a very significant role in the process of injection molding.

Gate Types:

There are two types of gates that are used in plastic injection molding: manually trimmed and automatically trimmed gates.

Manually trimmed gates are chosen for several reasons:

- The gate is too thick to be separated automatically

- Shear-sensitive materials such as PVC cannot be exposed to high shear rates

Automatically trimmed gates are used for several reasons:

- Avoiding gate removal as a secondary operation, reducing cost

- Maintaining consistent cycle times for all parts

- Minimizing gate scars on parts

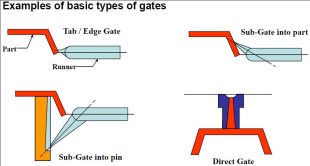

The largest factor to consider when choosing the proper gate type for your application is the gate design. There are many different gate designs available based on the size and shape of your part,four of the most commonly used are:

- The Edge Gate is the most common gate design. As the name indicates, this gate is located on the edge of the part and is best suited for flat parts. Edge gates are ideal for medium and thick sections and can be used on multicavity two plate tools. They leave a scar at the parting line.

- The Sub Gate is the only automatically trimmed gate on the list, and it requires ejector pins. A very common gate, it has a number of variations, such as a banana gate or tunnel gate. The sub gate allows you to gate away from the parting line, giving you more flexibility to place the gate at an optimum location on the part. This gate leaves a small scar on the part.

- The Hot Tip Gate is the most common of all hot runner gates. Hot tip gates are typically located at the top of a part as opposed to the parting line, this type of gate is great for conical or round shapes that require uniform flow. This type of gate requires a heated element to deliver hot material directly to the part, but it can improve flow and reduce cycle times. It leaves a small raised spot on the surface of the part.

- The Direct or Sprue Gate is a manually trimmed gate that is used for single cavity molds of large cylindrical parts that require symmetrical filling.Easy to design and with low maintenance costs, it produces parts that are typically lower stressed and high strength. This gate leaves a large scar on the part at the point of contact.

In our more than 15 years in plastic injection molding,we have significant expertise in this area and can provide tremendous insight on your mold design. Please visit us at :okmolding.com or via info@okmolding.com and let’s talk about your next project.

0 responses on "Plastic injection molding gate types & gate designs"